Whitepaper

Bypass Fume Hoods Compared Using CFD

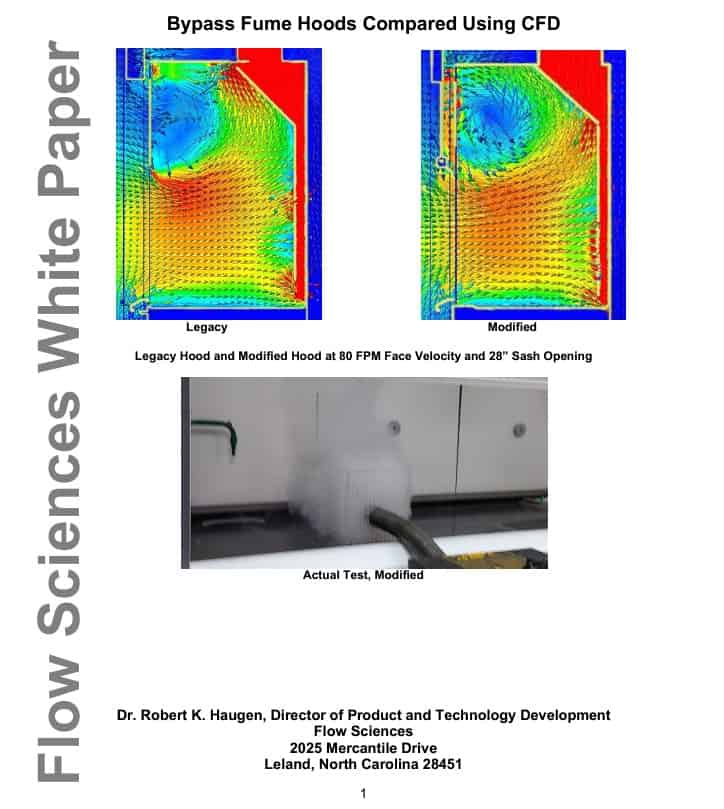

A Legacy (Standard) Flow Sciences fume hood was developed, modeled, and constructed using Auto Desk and CFD (Computational Fluid Dynamics) at our manufacturing facilities here at Flow Sciences. Containment analysis was done under:

1) “Standard conditions” (80 FPM face velocity and sash height of 28”)

2) “Low flow conditions” (60 FPM face velocity and 18” sash height)

In both normal flow and low-flow cases, air flow and potential containment issues were then identified and documented.

Next, the legacy hood baffle system, airfoil, and bypass were modified and new hood parts constructed reflecting design changes believed to help improve fume hood containment. The CFD analysis described above was then run again at the same face velocities with the modified hood.

The Modified Fume Hood performed significantly better than the Legacy model in the following areas:

1) Size and severity of upper front interior vortex area

2) Distribution of internal transport currents carrying fumes out of containment area

3) Worktop airflow

These theoretical advantages predicted by CFD comparisons were then tested using ASHEA 110 and other aerodynamic tests on the physically altered legacy hood. This testing showed the predicted improved results actually occurred.

The advantages suggested above by modeling and demonstrated with physical testing also offer a potential opportunity to save significant amounts of energy and simplify operation with lower flow options. The current Saf T Flow fume hood Flow Sciences offers is the “Modified” fume hood from this study.

Perhaps an even more significant result from the above analysis is the demonstration that CFD can save time and money in our industry’s efforts to rapidly produce and improve fume containment designs without physically testing each design change separately.