Congratulations, you have money allocated for a new hood or biosafety cabinet! Now comes an important decision: Which piece of equipment do you invest in? Both serve a similar purpose — a form of containment — but there are some distinct differences you should consider before placing your equipment order. Read on for everything you need to know about biological safety cabinets and laminar flow hoods before you make your decision.

What Are Biological Safety Cabinets?

Biological safety cabinets (pictured above) provide personnel, product and environmental protection from hazardous particulates that require Biosafety Level 1, 2 or 3 containment. The Centers for Disease Control and Prevention (CDC) defines biological safety cabinets (BSCs) as “the primary means of containment developed for working safely with infectious microorganisms.”

Due to the potentially hazardous nature of the materials that they contain, it’s important to keep safety best practices in mind when using a BSC:

- Avoid working with volatile or flammable chemicals in your BSC as these machines aren’t designed to properly protect users from toxic fumes or fire.

- Always maintain proper sash height when working at your BSC. For example, a sash that’s set too high affects inflow and downflow rates, risking product contamination.

- Make sure the airflow grill is free of obstructions. A blocked grill can result in contaminants that leak out into the laboratory environment.

- Be sure to dress properly. When working at the BSC, it’s crucial to wear protective gear such as a buttoned lab coat, eyewear and latex or nitrile gloves.

Types of Biological Safety Cabinets

There are three types of biological safety cabinets, which vary in levels of protection. Your choice of cabinet will depend on what level of protection you need for your workers, your space and your samples.

- Class I provides protection for you and the environment, but not your samples.

- Class II, which is the most common, provides protection for you and those in your lab, your samples and products and the environment. Additionally, within this class of BSC there are four sub-types: Type A1, Type A2, Type B1 and Type B2. The main difference is the percentage of air that recirculates within the cabinet vs. the percentage that leaves the cabinet through the exhaust HEPA filter. Also, A1 and A2 cabinets can either exhaust into the room or connect to the facility’s HVAC system, while B1 and B2 cabinets must connect to the facility’s HVAC system.For a full breakdown of how each type differs, we recommend taking a look at this chart from the American Biological Safety Association.

- Class III provides the most protection since the enclosure is gas-tight. These models include the same state-of-the-art features as the Class II cabinets, in addition to a primary physical barrier that offers protection between the lab worker and the biological agent.

To fully understand each level and what it offers, take a look at the following chart:

| Classification | Biosafety Level | Application |

| Class I | 1, 2, 3 | Low-to-moderate-risk biological agents |

| Class II | 1, 2, 3 | Low-to-moderate-risk biological agents |

| Class III | 4 | High-risk biological agents |

Biosafety levels are “used to identify the protective measures needed in a laboratory setting to protect workers, the environment, and the public,” according to the U.S. Department of Health and Human Services. You can find the complete breakdown of biosafety levels here.

Pros & Cons for Biological Safety Cabinets

Pros

- Flexibility — As we’ve mentioned, biological safety cabinets come in three levels, so you have options when it comes to the level of protection you need for your lab.

- Dependability — Biosafety cabinets also meet or exceed NSF/ANSI 49 – 2008, BioSafety Cabinetry: Design, Construction, Performance and Field Certification, an international standard for this type of protective lab equipment.

- Safety — All BSCs come with high efficiency particulate air (HEPA) filtration, an audible alarm and a flashing LED screen to indicate when the sliding viewscreen is in an unsafe position. Some models that require connection to HVAC systems feature an audible/visual airflow alarm and airflow monitor (AFM), which warns when the exhaust airflow decreases.

- Cost savings — Some energy efficient models can even save you up to 70% annually in operating costs due to a large reduction in energy consumption and heat yields.

Cons

- Higher initial investment — BSCs tend to be more expensive to purchase than laminar flow hoods.

- Size — BSCs are also large, so you need to make sure you have the floor space and ceiling height to accommodate this type of lab equipment.

What Are Laminar Flow Clean Benches?

Laminar flow clean benches (pictured above), also sometimes known as laminar flow hoods, protect products and samples in a variety of life science, industrial lab and process applications. But it’s important to note that they don’t provide protection for lab workers or the environment. Laminar flow hoods provide a sterile environment for the sample, but you aren’t protected from airflow, which is why working with harmful or toxic materials or chemicals with this type of equipment is strongly discouraged.

Safety best practices for laminar flow hoods include:

- As in BSC safety, never work with toxic or flammable chemicals in your laminar flow hood. These units are also not designed to protect users from toxic fumes or fires.

- Always maintain the correct position when working in your laminar flow hood. Your hands and arms are the only body parts that should enter the unit; placing your head and shoulders even slightly inside the hood can result in sample contamination.

- Be sure to wear your personal protective equipment (PPE) correctly. This includes a back-fastened lab coat and double gloves worn over the cuff.

Types of Laminar Flow Clean Benches

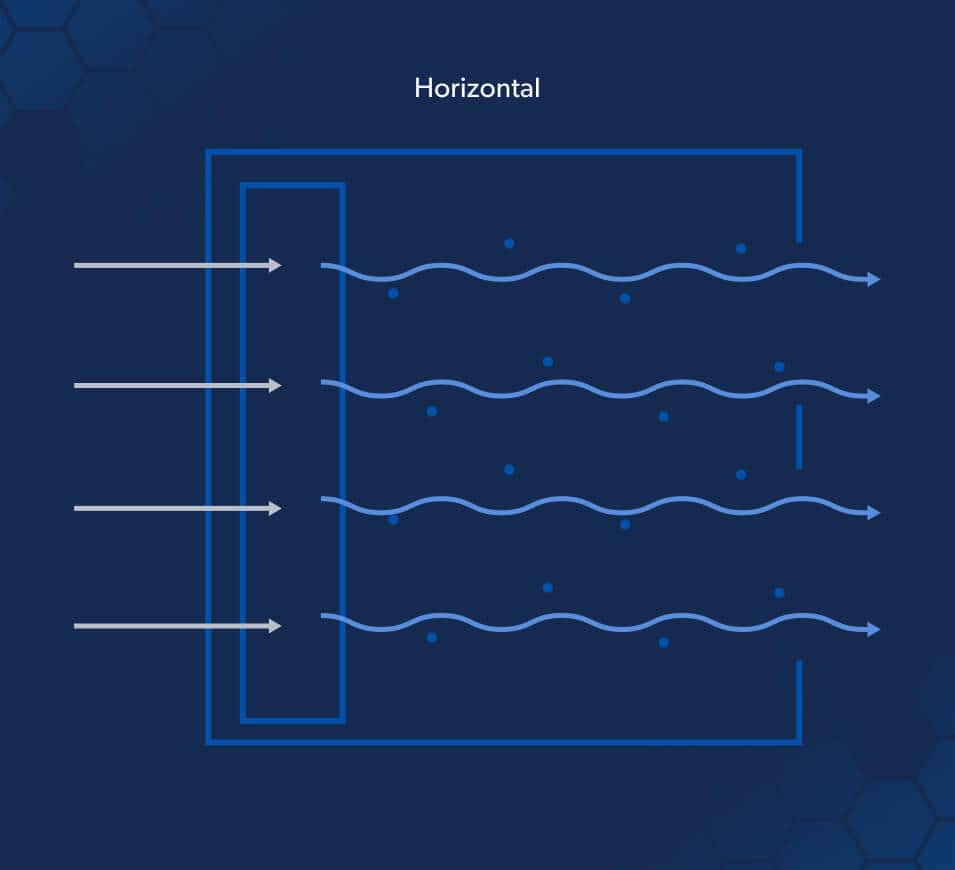

The two types of laminar hoods can be distinguished by the direction of the airflow within the hood — either horizontal or vertical. Each type is designed with specific purposes in mind, with each best suited for a unique set of purposes.

Horizontal Laminar Flow Clean Benches

These hoods are best suited for applications that involve low-risk agents, including:

- Sterile product preparation

- Sterile drug compounding

- IV admixture preparation

- Plant cell culture

- Media preparation

- Pharmaceutical procedures

Vertical Laminar Flow Clean Benches

These models are ideal for when product protection and particulate control are required. They are also designed for the same variety of industry applications as horizontal laminar flow hoods.

Pros & Cons of Laminar Flow Clean Benches

Pros

- Airflow options — Laminar flow hoods come in two models, vertical and horizontal, depending on the desired direction of your airflow. If space is tight in your lab, consider a vertical model, which isn’t as deep. Space-saving models are great for limited areas such as IV and nursing stations, satellite pharmacies and intensive care units.

- Compliance — All laminar hood models comply with standards from the International Organization for Standardization (ISO), which provides classifications for cleanrooms and the air inside them.

Cons

- Lack of user protection — While a laminar flow hood is an important piece of equipment that protects your samples, it doesn’t offer protection for you and your colleagues in the lab.

- Lack of versatility — Even though you currently might only need the product protection that a laminar flow hood provides, the nature of your research/work could change in the future — meaning you may need to switch to a BSC instead.

Biological Safety Cabinets vs. Laminar Flow Hoods: What’s the Difference?

While both BSCs and laminar flow hoods are essential pieces of laboratory equipment that serve similar functions, there are significant differences between the two when it comes to the protections they offer, their applications and airflow patterns. Let’s take a closer look at each differentiator:

Protections

When choosing equipment for your lab, it’s crucial to understand that BSCs and laminar flow hoods have different sets of protections and the equipment you need will depend on the kinds of processes you and your staff members carry out on a regular basis.

Because they protect users, the surrounding environment and the product (except for Class I machines) against biohazards and dangerous particulate matter, BSCs are needed when working with hazardous biological materials.

On the other hand, laminar flow clean benches only protect the product from contaminants and not the user. This is why you must only use these pieces of equipment for processes that involve non-hazardous materials.

Applications

As their name suggests, biological safety cabinets are intended for use in labs that work with or research infectious microorganisms or other potentially hazardous particulate matter. The volatility of these products will determine the class of BSC needed to maintain safety for staff members, with Class I and II capable of handling low-to-moderate risk biological agents and class III units intended for high-risk substances.

Because they don’t offer the same protections as BSCs, laminar airflow hoods should only be used for non-hazardous tasks, such as preparing tissue cultures, working with semiconductors, preparation of media and use of sensitive materials.

Airflow

When it comes to the airflow in biological safety cabinets, patterns differ across the three different classes. In Class I units, air moves away from the user and is pulled backwards across the work surface (which provides protection for users, but not the product).

In general, Class II models circulate air by moving it around the user and underneath the work surface. Air that’s been filtered by a HEPA filter is also blown from above onto the work surface, while exhaust air passes through the filter before being recirculated or released into the atmosphere via ductwork.

However, there are subtle differences depending on what type of Class II BSC you use in your lab. For example:

- In Type A1 and A2 cabinets, 70% of the air recirculates throughout the cabinet and the remaining 30% of the air leaves the cabinet through an exhaust HEPA filter before either going into the room or entering the building’s exhaust system.

- With Type B1 cabinets, a portion of the air also recirculates throughout the cabinet. However, exhausted air gets pulled through a dedicated duct before moving through the exhaust HEPA filter and into the building’s exhaust system. B1 cabinets must be connected to the exhaust system.

- Finally, Type B2 cabinets do not recirculate air within the workspace and are hard-connected to the building’s HVAC setup. Instead of recirculation, these units exhaust filtered air directly into the HVAC system while air from the room gets pulled in via a blower, passes through the filter and into the workspace. Any descending air or air that enters from the unit’s front opening by the sash gets pulled through grills located in the front and rear.

Unlike class I and II BSCs, Class III models are enclosed, making them gas tight. Their intake and exhaust air undergoes HEPA filtration.

For laminar flow hoods, airflow is much more straightforward: Horizontal hoods feature horizontal airflow that pushes air over the work surface toward the user while vertical hoods have vertical airflow that draws air from above and pushes it down on top of the work surface. In both types, air first passes through a HEPA filter.

Choosing Between Biological Safety Cabinets & Laminar Flow Hoods

Now that you’ve weighed the pros and cons and understand what each piece of equipment is best used for, it’s time to make the decision — which one do you need for your laboratory? To help make your choice easier, we’ve included the following comparison chart:

| Biological Safety Cabinet | Laminar Flow Hood | |

| Intended Use | Laboratory work that involves hazardous or infectious materials and organisms | Low-to-moderate-risk biological agents |

| Types | Class I Class II

Class III |

Horizontal Vertical |

| Protections | Protects user from hazardous contaminants

Protects product from contaminants (class II and class III only) |

Protects product from contaminants |

| Pros & Cons | Pros — Protection flexibility, dependability, safety, cost savings

Cons — Higher initial investment, size |

Pros — Airflow options, compliance

Cons — Lack of user protection, lack of versatility |

D.A.I. Scientific Is Your Trusted Choice for Lab Equipment

Biological safety cabinets and laminar flow hoods are both important pieces of lab equipment, but there are some major differences — and the last thing you want to do is order the wrong type or model. We know the process of selecting new equipment can be overwhelming, but don’t worry — we’re here to help!

The experts at D.A.I. Scientific are familiar with every type of analytical laboratory in the pharmaceutical, educational, clinical and biotech industries. What sets us apart is our commitment to understanding and supporting our products. Do you have questions about temperature monitoring, equipment capacity, voltage or dimensions? Our highly qualified staff has the answers and will find the right equipment for you.

We have what you need to get started, and we’d be more than happy to answer your questions about which biological safety cabinet or laminar hood is the best fit for your space. Contact us today to get started!

FAQs

Q: When should you choose a biological safety cabinet?

A: You should opt for a BSC when you’re looking for the utmost protection, especially from hazardous, toxic or infectious droplets, aerosols and materials.

Q: What’s the difference between a horizontal and vertical laminar flow clean bench?

A: The difference is the direction of airflow within the hood.

Q: What’s the difference between a fume hood and a biosafety cabinet?

A: A BSC provides protection from hazardous materials with HEPA filters that treat and exhaust air. Fume hoods provide personnel protection by keeping harmful vapors from the breathing zone of the users, but your samples are in unfiltered air, so there is no product protection.

Q: When is a vertical laminar flow cabinet the best choice?

A: They are ideal for when you are working with non-hazardous samples that require product protection with clean HEPA-filtered air.

Q: What are the different Class II BSC types?

A: Class II BSCs also have four sub-types: Type A1, Type A2, Type B1 and Type B2. While they all provide the same protections — personnel, product and environmental — each type features unique airflow characteristics and exhaust connection requirements.

Q: Why would I vent a Class II A2 BSC?

A: If your samples have an order to them, a non-ducted BSC would have those orders go back into the room. Also, a vented BSC does give you another level of protection. If somehow your exhaust HEPA filter became damaged, the potential contaminated exhausted air is not going back to the lab.

Q: Why would I choose a Class II B2 BSC instead of a vented Class II A2 BSC?

A: The A2 cabinet recirculates 70% of the air within the cabinet and exhausts 30%. If your work generates vapors, these vapors will get built up in a recirculating BSC. The B2 BSC is 100% exhaust, so there is no buildup of vapors.

Q: Can my workers be exposed by the UV light within a BSC?

A: No, most modern day BSC manufacturers have built-in safety interlocks that turn off a UV light if the sash is opened.