When it comes to purchasing a new ultra-low freezer, there’s a lot to consider before you submit your equipment order. It’s safe to say you’ve thought about cost, but have you considered energy efficiency? Preventive maintenance? Warranty plans?

You want to make the right choice, because the wrong one can prove costly.

But first, let’s talk about the basics and the different types.

What is an Ultra-Low Temperature Freezer?

An ultra-low temperature freezer is a unit that preserves and stores biological samples within a temperature range of -50°C to -86 °C. They are mostly used within the life sciences and by clinical labs to store samples for an extended period of time; key applications include storage for vaccines, biomolecules, products for medical procedures and biospecimens, according to Lab Manager.

What are the Different Types of Ultra-Low Freezers?

Upright freezers: Inventory rack options can provide better organization and the upright configuration compartments make it easier to reach samples. These units take up less valuable floor space.

Chest freezers: Chest freezers hold temperatures better during door openings than an upright freezer. These are not as popular because of the large footprint.

Top 10 Considerations

Now let’s talk about what you need to think about before you make a purchase.

1. Reliability

How do you know if a freezer is reliable? Good question. Just as you would with most other products, it’s important to do your homework and research different manufacturers. Ask colleagues who work in other clinics and labs for recommendations and look for trusted, reputable brands that offer peak reliability and dependable compressors. You also want an ultra-low freezer model that’s been around for awhile — in order words, a piece of equipment that has good reviews and is proven to work.

If you need an ultra-low freezer for vaccine storage, it’s important to determine whether the units follow CDC or Vaccine for Children (VFC) storage guidelines.

2. Usability

Look for units that provide the features you need, such as alarms and temperature monitoring. This freezer need

s to work for you, your research and your lab. Here are some important questions to ask when it comes to usability:

- How does your freezer deal with frost and ice buildup?

- What are the external dimensions of the freezer?

- Will the unit fit comfortably in your lab?

- What are the voltage requirements?

3. Sustainability & Energy Efficiency

Laboratory cold-storage equipment typically uses a lot of energy, and ultra-low freezers are one of the worst offenders. They consume high amounts of energy in order to protect your samples and maintain the temperature when you open the door. According to the U.S. Department of Energy, an ultra-low temperature freezer uses the same amount of energy per day as the average household.

If you’re looking for a sustainable option, it’s important to confirm that your ultra-low freezer has the ENERGY STAR® label, which will ensure that your units have the latest in energy-saving features. This is important because it will help lower your utility bills.

ENERGY STAR units reduce energy consumption through the use of more efficient compressors, advanced microprocessor controllers and innovative and environmentally-friendly refrigerants.

Check out the ENERGY STAR website to compare energy consumption that’s tested by a third-party independent lab.

4. Convenience

This is something you might not typically consider, but is the ultra-low freezer convenient for you and your lab’s needs? For example, underlying compressors can reduce freezer noise, which may be helpful if you’re looking for a quieter lab environment.

You also need to consider power and voltage requirements. Does your lab have the appropriate electrical resources in place, or do you need a professional to come in and install what you need?

You want to make sure you have the right resources hooked up and ready to go before your equipment arrives. Your sales specialist can help ensure that you have the correct services in your lab and that they are located in the right areas for easy installation.

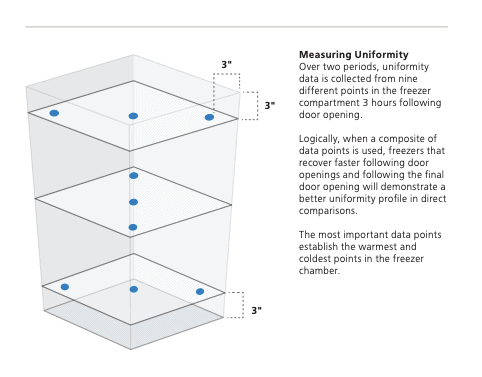

5. Temperature Uniformity

What happens if your ultra-low freezer starts to warm up? How quickly does the temperature return to normal after you open

the door? These are important questions to ask.

Most modern units come standard with local alarms that notify the user when there’s an issue, which is especially important if your freezer starts to warm during off-hours when no one is in the lab.

Talk to your sales rep about an independent monitoring system that will not only log temperatures for reporting, but will also notify you via text, email or a phone call if your unit is not at the correct temperature. You can also ask ultra-low freezer manufacturers for reliable data and information to prove the unit has temperature uniformity.

6. Placement and Facility Concerns

Where will your freezer be placed in your lab? One of the first steps is to measure the space in your lab where your new ultra-low freezer will reside. It’s important to accurately document the height, width and depth of the space and match it to the dimensions of your freezer to ensure there are no surprises when the equipment arrives.

Here are some important questions to keep in mind:

- Do you have the space you need to load the freezer with materials or equipment?

- Do you have the proper space for your work?

- Have you assessed the overall space for the workflow of your lab? (For example, when you’re loading and unloading the freezer, where do the samples wait, and where do they go after unloading?

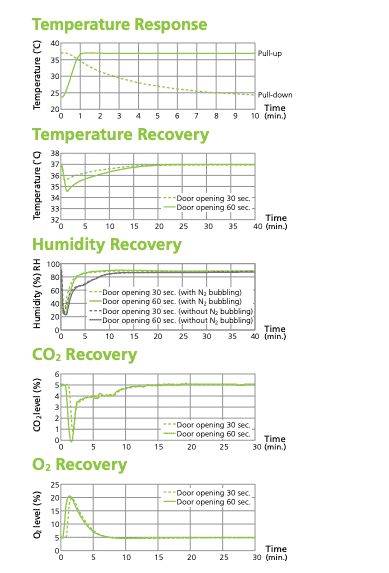

7. Backup Plan

No one wants to think about it, but problems happen, which is why it’s always important to have an equipment backup plan. In addition to looking for a reputable, dependable ultra-low freezer with good reviews, you should consider a facility that has backup emergency power options, which will protect your equipment in the event you lose power.

CO2 backup systems are a common option. Also, some companies have a built-in backup system where in the event of a compressor failure the freezer can run on one compressor and still maintain ultra-low temperatures. See the chart to see what good recovery times look like in the event of an emergency.

8. Warranty

Ultra-low freezers (and all types of lab equipment) come with a warranty, but there are often restrictions. A typical one is covering parts but not labor, which is the most expensive part of most repairs. Some warranties require a preventative maintenance program, and if you don’t have this, your warranty is not valid.

The bottom line: It’s important to talk about the warranty details with your sales rep. You can also ask if there’s an extended warranty, which can be a wise investment if your budget allows for it.

9. Maintenance Concern and Prevention

Any piece of lab equipment that you buy will likely need to be serviced at some point, and ultra-low freezers are no exception. That’s why when you’re buying a new piece of equipment, it’s important to find out how your product is supported. What’s the maintenance plan for your ultra-low freezer?

You also want to learn what you can do to prevent any major repairs. For example, typical proper maintenance for ultra-low freezers includes regularly washing, checking or replacing filters as needed and cleaning coils with a wet towel, brush or vacuum.

10. Price

Budget is always a top concern, especially since almost all organizations and institutions are working with a set amount of money.

You want to compare the price with all of its features. Are any levels of service and maintenance included? What are the details of the warranty policy?

Many manufacturers have different ultra-low freezer models with a “good, better, best” philosophy, which allows for different budgets. In many cases, the freezer with the higher initial cost will end up being more cost-effective in the long run due to the longer warranty periods, less scheduled maintenance and because it will be a more reliable unit with less downtime. You also want to consider these other factors, which can impact the cost:

- Equipment controllers and control systems

- Automated features

- Energy-efficient/sustainability features

- Custom design options

- Equipment material

- Additional accessories or features that may be included

FAQs

Q: What are the electrical requirements, and what kind of plug comes with the freezer?

A: Most freezers have two choices for voltage: 115V or 220V. The plug configuration does change depending on the voltage. Consult with your sales representative for more details.

Q: What kind of inventory systems come with your freezers?

A: There is a large selection of inventory racks ranging from boxes and conical tubes to custom racks. Your local sales rep can cover all the options.

Q: How much space should I allow around the freezer?

A: Most manufacturers say 4″ to 6″.

Q: Are the shelves adjustable, and can I add more?

A: Yes, they are adjustable, and you can always add more shelves.

Q: Can my monitoring system connect to the freezer?

A: Most freezers come with an access port so that you can run a temperature probe into the freezer compartment or a remote alarm terminal.

Looking for an Ultra-Low Temperature Freezer?

D.A.I. Scientific has a long history of working with market-leading ultra-low freezer manufacturers to provide high-quality products to analytical laboratories in the pharmaceutical, educational, biotechnology and clinical industries. If you have questions about these types of freezers, or you’re looking for more information, contact us and we’ll be in touch. Our factory-trained sales representatives have the specialized knowledge to answer your questions and help you pick out the right ultra-low freezer for your lab.