Manufacturers Trust D.A.I. Scientific

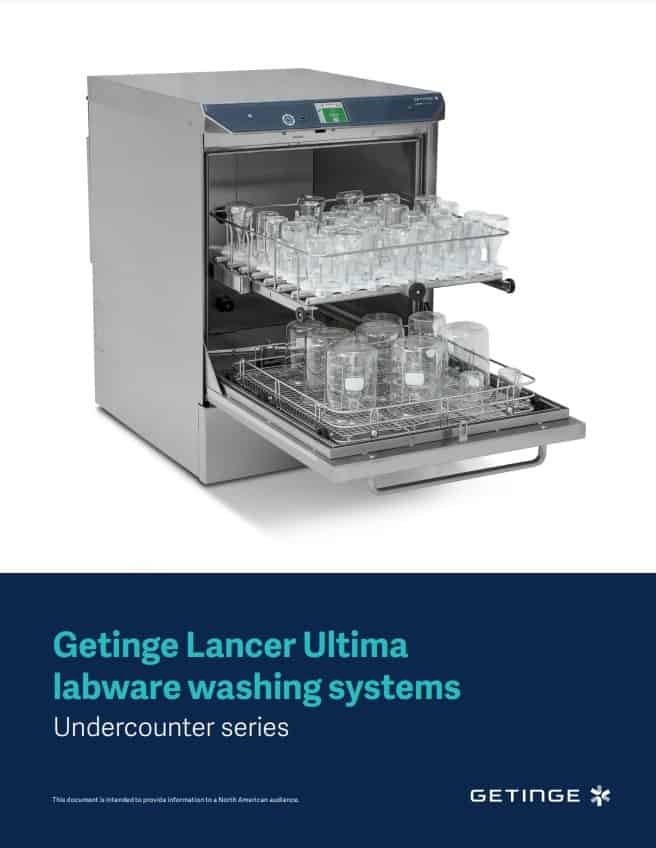

D.A.I. is proud to continue a 10+ year partnership with Getinge Lancer to offer best-in-class products for glassware washing. Their laboratory washers efficiently ensure contamination-free experiments and tests.

DAI is proud to announce a new partnership with Beckman Coulter. If you are looking for a centrifuge, check out what we have. View Centrifuges

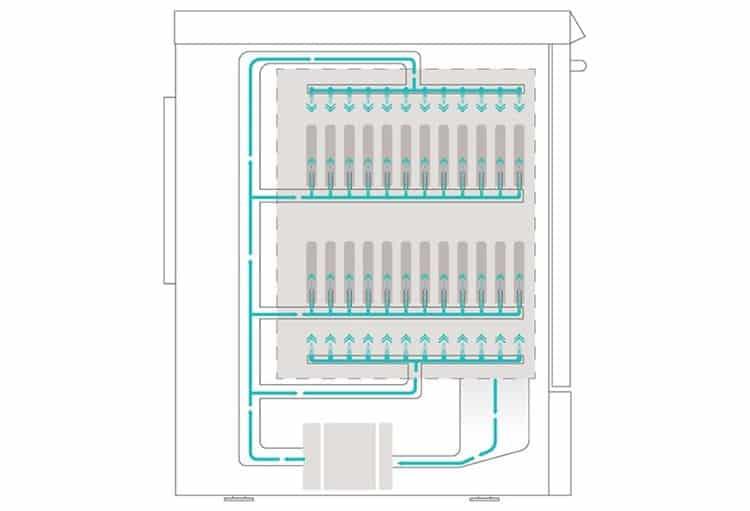

In addition to direct injection cleaning on two levels, the 820 LX provides complete drying coverage inside and outside of processed glassware. HEPA-filtered air is forced through both the chamber and injectors, ensuring complete drying in a quick overall cycle time. The 820 LX also offers onboard storage of chemicals within the frame of the washer for safe storage and protection from unnecessary handling.

D.A.I. is proud to continue a 10+ year partnership with Getinge Lancer to offer best-in-class products for glassware washing. Their laboratory washers efficiently ensure contamination-free experiments and tests.

Washers by Getinge Lancer are designed to provide complete coverage of both the interior and exterior of glassware. Maximizing water flow, the hydraulic systems deliver a direct fluid path to pressurized top and bottom stainless steel spray arms and each individual rack, providing a comprehensive and effective cleaning performance.

Getinge Lancer washers minimize environmental impact and maximize cleaning performance. Microprocessor controls provide programmable cycles that offer the exact combination of water, and peristaltic pumps deliver accurate dosing of detergent and acid. Optional conductivity measurement ensures consistent processing with no chemical residues on processed goods.

Getinge Lancer provides a broad range of washing accessories to cover all your glassware needs, including beakers, flasks, bottles, tubes, pipettes and much more. These options are critical to proper loading of the washer to ensure successful cleaning and throughput.