Incubators

Incubators are a critical piece of equipment for research and clinical labs, and the models we offer are made to hold tight temperature and gas uniformity. They have built-in passive and active decontamination features that ensure the incubator will successfully grow your cultures without the fear of contamination or downtime.

-

Heated IncubatorsThese units maintain a controlled, constant temperature environment, primarily used to cultivate microorganisms, cells, …View Products

Heated IncubatorsThese units maintain a controlled, constant temperature environment, primarily used to cultivate microorganisms, cells, …View Products -

CO2 IncubatorsCO2 incubators from PHCbi (formerly Panasonic) and Baker Company provide a uniform and consistent environment, which is …View Products

CO2 IncubatorsCO2 incubators from PHCbi (formerly Panasonic) and Baker Company provide a uniform and consistent environment, which is …View Products -

Multi-Gas IncubatorsMulti-gas incubators use a combination of CO2 and nitrogen gases to simulate in vivo conditions. PHCbi (formerly Panason …View Products

Multi-Gas IncubatorsMulti-gas incubators use a combination of CO2 and nitrogen gases to simulate in vivo conditions. PHCbi (formerly Panason …View Products -

Microbiological and Refrigerated IncubatorsPHCbi (formerly Panasonic) has a full line of microbiological incubators that are made for applications that require pre …View Products

Microbiological and Refrigerated IncubatorsPHCbi (formerly Panasonic) has a full line of microbiological incubators that are made for applications that require pre …View Products -

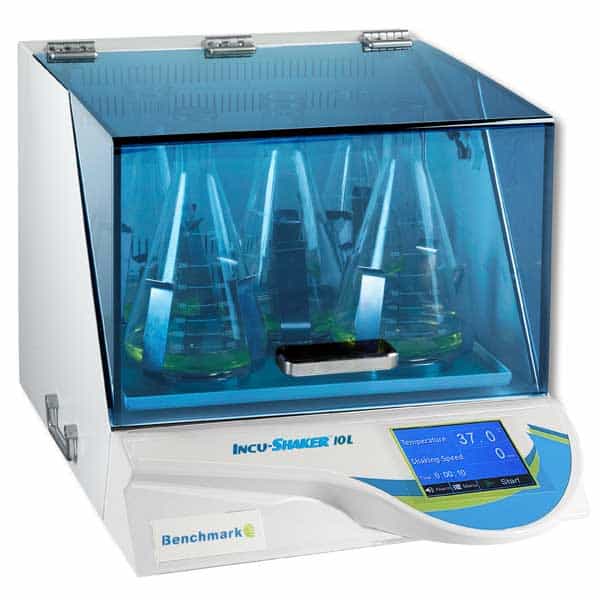

Shaking IncubatorsFor labs that need the function of an incubator and the capabilities of a shaker, shaking incubators are an ideal soluti …View Products

Shaking IncubatorsFor labs that need the function of an incubator and the capabilities of a shaker, shaking incubators are an ideal soluti …View Products -

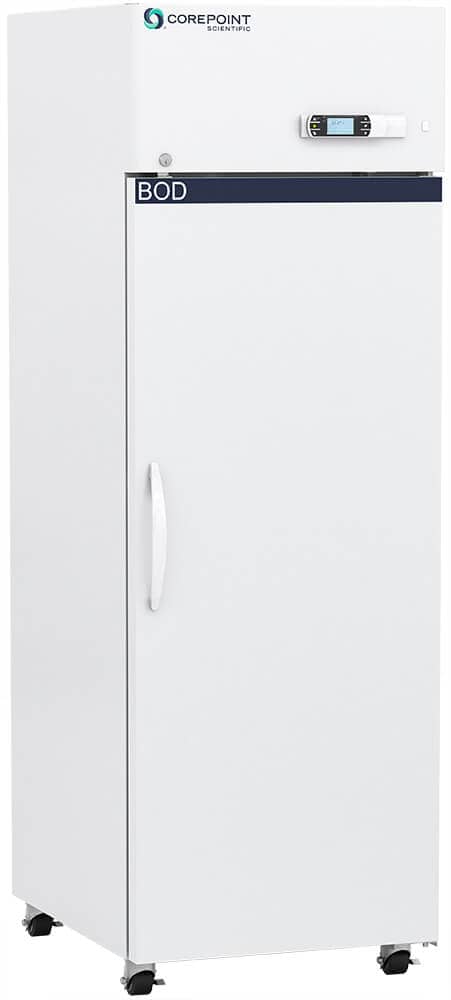

BOD IncubatorsA BOD (Biochemical Oxygen Demand) incubator has both cooling and heating options. With its variable-speed compressor, pr …View Products

BOD IncubatorsA BOD (Biochemical Oxygen Demand) incubator has both cooling and heating options. With its variable-speed compressor, pr …View Products

Incubator Considerations

- Type of unit: Choose from four different types of incubators: CO2, multi-gas, microbiological, or shaking. A CO2 incubator is a gassed unit that creates an ideal atmosphere for developing cell cultures. A multi-gas incubator uses a combination of CO2 and nitrogen to simulate in vivo conditions. A microbiological incubator is ideal for applications that require precise temperature control. A shaking incubator combines the features of a traditional CO2 incubator with shaking and orbital agitation at variable speeds to enhance the growth of cells.

- Capacity: Our CO2 incubators are available in a range of sizes from 1.7 to 30.1 cubic feet. Multi-gas incubators range from 1.8 to 5.7 cubic feet and microbiological incubators from 3.3 to 49 cubic feet. We also offer a variety of shaking incubators, including the AEOLUS™ IS-18CA CO2 that has a stackable design to help maximize floor space with the capacity to stack up to three units high.

- Humidity control: All our CO2 incubators provide humidification. If you’re looking for more humidity control, the Baker REC 602 Recover CO2 incubator provides a relative humidity control range that comes in two operating modes — up to 90% and 90%–95.

- CO2 sensor technology: Our incubators feature two different types of CO2 sensors — a thermal conductivity detector (TCD) and an IR sensor. A TCD sensor relies on temperature and humidity levels to properly read CO2. Opening the incubator door affects temperature and humidity levels, which means it could take at least a half hour for the temperature and humidity levels to stabilize. Incubators with a TCD sensor might be sufficient for long-term storage of cultures, but they’re less suitable for situations where door openings are frequent. Infrared sensors rely on the fact that CO2, like other gasses, absorb a specific wavelength of light.

- Oxygen control: Some of our incubators have the ability to control oxygen levels, which can allow for more optimal growing conditions.

- Contamination control: Contamination is a high priority in any lab, and our incubators have a large selection of passive and active contamination control features. The copper alloy stainless steel interior on the PHCbi InCu-saFe is an example of a passive contamination control, whereas H202, high heat and UV light are all active contamination control features.

- ISO classes: Some of our models comply with standards from the International Organization for Standardization (ISO), which provides classifications for cleanrooms and the air inside them. Please reach out to your local rep for help in choosing models for your cleanroom.

Common Incubator Applications

Incubators are designed for a variety of industry applications:

- Pharmaceutical research and testing

- Bacteria, cell culture and microorganism growth

- Insect breeding

- Sample storage

- Vitro cell culture environment

- Clinical medicine processes

- Food analysis

Testimonials

Never breaks! Fantastic, personal support for sales, delivery, setup, and troubleshooting.

Lab at Washington University

FAQs

What does an incubator do?

An incubator provides temperature and gas uniformity in order to grow and maintain the growth of cultures without fear of decontamination.

How does an incubator work?

An incubator is an insulated unit equipped with a variety of features that allow you to control the temperature, humidity and CO2 levels in order to create the optimal working or growing conditions.

What do you need to set up an incubator?

All incubators need electricity and CO2, and multi-gas incubators need a combination of CO2 and nitrogen. This can be supplied by a stand-alone gas cylinder, though some labs may have a manifold system that pipes the gas into the incubator.

What is an incubator used for?

Laboratory incubators are typically used to grow bacteria or other types of microorganisms in a controlled environment. This could include pharmaceutical or biology testing or insect breeding. Some incubators are used to maintain the growth of a cell culture or store samples in which certain environmental conditions are needed.

Can't find the product you're looking for? We'll help you figure it out.

Contact Us